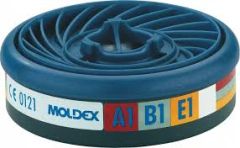

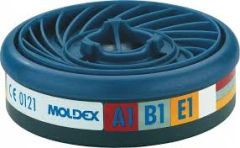

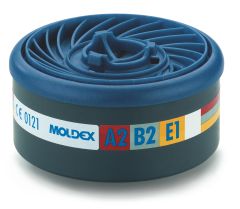

Moldex A2 Filter Cartridges (Pack10) (Moldex 7000/9000) (Code 9200)

Christmas-New Year Dispatch Dates:

- 21st December midday cut off.

Any orders placed after this date will be processed.

- 28th December midday cut off.

- 29th December midday cut off.

- Next dispatch date: 2nd January 2024.

- Whilst standard delivery is stated as 1-3 days we are currently delivering over 99% of orders the next business day as a standard service if placed before 2.30 pm.

Delivery Options:

- Standard Delivery: (1-3 business days) (£ 5.75 - £ 6.20)

- Next Business Day Delivery: (Order Must be placed before 2 pm) (£ 9.50 ex vat)

- Next Day Working Day Delivery Pre 12 delivery (Order Must be placed before 2 pm): £ 11.50 ex vat

- Next Working Day Delivery Pre 10.30 delivery (Order Must be placed before 2 pm): £ 13.95 ex vat

- Weekend Delivery Options:

- Saturday Delivery: (Order Must be placed before 12 pm) £ 22.50 ex vat

FREE DELIVERY OVER £ 75 NET

- The free delivery over £ 75 net is only available for UK mainland.

- Deliveries to Islands and highlands are a 2-3 day delivery option only & charged at £ 16 ex vat.

We found other products you might like!

Frequently Asked Questions

01: What vapour or particulate filters are required?

Organic fume Filters are graded depending on the concentration of contaminant. Class 1 is up to 1000ppm, Class 2 is up to 5000 ppm & class 3 up to 10,000 ppm.

Combination filters ie mask filters that act as both fume filters & particulate filters protect against both gases/vapours and particulates must meet the relevant standards for each element.

02: How long do mask filters last?

The length of the service life of the mask filter is dependent on a number of factors:

- Concentration of contaminant (The dustier / higher contamination in the environment the more frequently the mask filter will need to be changed)

- Air humidity / Air temperature

- How hard the mask wearer is breathing

03: What are the particulate filter grades?

Particulate filters are classified according to the level of filtering efficiency & protection that they provide.

The filters will be either be P1 (Low filter efficiency), P2 (Medium filter efficiency) or P3 (High filter efficiency & protection.

04: What do particulate filters protect against?

P filters can be used to provide filter protection from both solid particles as well as fine mists and sprays. The size of particulate that is filtered will range from a particle size of 5 microns for a P1 down to as low as 0.3 microns for a P3 filter. (High level protection)

Any particles or fibres are held within the filter as well as the fine sprays or mist generated from aerosol procedures.

05: What examples of solid materials do P filters protect against?

Depending on the P filter selected, the hazardous particulates may include:

- Viruses & Bacteria (P3 Filter)

- Asbestos dust (P3 filter)

- Silica (P3 filter)

- Lead dust (P3 filter)

- Fungal spores (P2 filter)

- Flour (P2 filter)

- Wood Dust (Soft Wood P2 filter, Hard Wood P3 filter)

06: What examples of spray or mists do P filters protect against?

Liquid sprays & mists that P filters protect against include:

- Spray Paints

- Pesticides

- Powder coating

- Chrome acid

- Oil mists

07: What is a P3 filter?

P3 levels are the highest rated level of P filter and is used in conjunction with either a Half Mask or Full Face Mask for protection against highly toxic or irritant particulates, vapours & viruses. P3 filters

An APF protection level of 20 APF when used with a Half Mask & 40 APF when the P3 filter is used with a Full Face Mask.

08: When do you know when to change a particulate filter?

Particulate filters should be changed when breathing resistance becomes difficult (ie breathing resistance created through the blocking of the filter)

09: When should I change my P3 filter?

P3 filters should be changed when breathing resistance is encountered. This is dependent on the level of contaminant encountered.

10: When do you know when to change a gas/vapour/ fume filter?

Gas / vapours / fume filters should be changed as soon as “smell breakthrough” occurs (ie safe levels of contaminant smelt/tasted)

N.B for substances with no smell or taste i.e low warning properties supplied air respirators should be used rather than masks & filters since any “smell breakthrough” cannot be detected. i.e isocyanates.

11: What mask filter would I require to protect against Aceton?

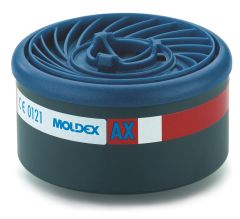

Fume Filter Type AX:

An AX Filter type is required providing protection from gase & vapours from organic compounds boiling point <65 degrees.

12: What Fume filters are required for handling solvent vapours when painting and varnishing?

Fume Filter Type A:

An organic fume filter cartridge Type A organic filter providing protection from gases & vapours from organic compounds, boiling point >65 degrees. (Use in combination with a P filter (Particulate filter)

13: What mask filter protection do I need for welding processes?

Fume Filter Type B:

A filter Type B protection is required. A filter including Type B will provide protection against inorganic gases & vapours & acid gases. (For example, Chlorine, hydrogen sulphide & hydrocyanic acid.

Should be used in combination with a P mask filter (Particulate filter) -ABE-P filter.

14: What mask filter protection do I need for welding processes?

Fume Filter type E:

Acid gases are released which require adequate RPE to be worn. An ABE-P (Ie gas & fume filter) is required to protect against acid gases and fumes to include Sulphur Dioxide & Hydrogen Chloride.

15: What mask filter do I need for ammonia & liquid fertilisers?

Fume Filter Type K:

The filter including K will protect against Ammonia & organic ammonia derivatives. If powdered fertiliser is used or vapours are created the mask filter should also be used with a P Filter. (P3 filter)

ABEK1 – P, ABEK, ABE, ABEK1P3.

16: What filter will protect me against Carbon monoxide?

The filter CO will protect against carbon monoxide. These are used with escape hoods to protect against gase during fires or for handling hydrogen peroxide.

17: What filters do I require to protect against Mercury Vapour?

Fume Filter type HG:

A filter containing HG will protect against mercury vapour. This must be included with P filter to protect against chemicals Ie ABEKHGP3 filter.

18: What filter do I need to protect against fine dusts & viruses?

Particulate Filter Type P:

A P filter is required to protect against dusts. A P3 filter is required to protect against very fine dusts & to provide protection against viruses.